Lawrence Edward Crawford, MD

- Associate Professor of Medicine

https://medicine.duke.edu/faculty/lawrence-edward-crawford-md

Therefore birth control usage statistics buy yasmin paypal, neither pregnancy nor lactation should be considered a contraindication to vaccination of women birth control pills time generic yasmin 3.03mg free shipping. No clinical trials have been conducted to assess postexposure use of antiviral agents birth control for women good order yasmin 3.03 mg line. Available data suggest that an established infection might need to be present before interferon can be an effective treatment birth control pills effect on pregnancy order yasmin cheap. During the first phase birth control pills weight gain discount yasmin 3.03 mg with visa, interferon blocks the production or release of virus from infected cells birth control pills prices buy 3.03 mg yasmin with mastercard. Data from studies conducted outside the United States suggest that a short course of interferon started early in the course of acute hepatitis C is associated with a higher rate of resolved infection than that achieved when therapy is begun after chronic hepatitis C has been well established (90-92). No studies have evaluated the treatment of acute infection in persons with no evidence of liver disease (i. A laboratory study that demonstrated that more blood is transferred by deeper injuries and hollow-bore needles lends further support for the observed variation in risk related to blood quantity (101). The use of source person viral load as a surrogate measure of viral titer for assessing transmission risk has not yet been established. Over the subsequent 24-48 hours, migration of these cells to regional lymph nodes occurred, and virus was detectable in the peripheral blood within 5 days (110). Data from animal studies have been difficult to interpret, in part, because of problems identifying an animal model that is comparable to humans. Recently, refinements in methodology have facilitated more relevant studies; in particular, the viral inocula used in animal studies have been reduced to levels more analogous to human exposures but sufficient to cause infection in control animals (111- 113). These studies provide encouraging evidence of postexposure chemoprophylactic efficacy. In the same study, protection was incomplete if the tenofovir administration was delayed to 48 or 72 hours postexposure or if the total duration of treatment was curtailed to 3 or 10 days (123). Thirteen of the source persons were known to have been treated with antiretroviral therapy before the exposure. A combination of drugs with activity at different stages in the viral replication cycle. Although the use of a three-drug regimen might be justified for exposures that pose an increased risk of transmission, whether the potential added toxicity of a third drug is justified for lower risk exposures is uncertain. Therefore, the toxicity profile of antiretroviral agents, including the frequency, severity, duration, and reversibility of side effects, is a relevant consideration. All of the antiretroviral agents have been associated with side effects (Table 2). However, studies of adverse events have been conducted primarily with persons who have advanced disease (and longer treatment courses) and who therefore might not reflect the experience in persons who are uninfected (144). All of the approved antiretroviral agents might have potentially serious drug interactions when used with certain other drugs (Appendix C). These events included 12 cases of hepatotoxicity, 14 cases of skin reaction (including one documented and two possible cases of Stevens-Johnson syndrome), and one case of rhabdomyolysis; four cases involved both hepatotoxicty and skin reaction, and one case involved both rhabdomyolysis and skin reaction. Despite recent studies and case reports, the relevance of exposure to a resistant virus is still not well understood. Empiric decisions about the presence of antiretroviral drug resistance are often difficult to make because patients generally take more than one antiretroviral agent. Data are limited on the potential effects of antiretroviral drugs on the developing fetus or neonate (156). Recent reports of fatal and nonfatal lactic acidosis in pregnant women treated throughout gestation with a combination of d4T and ddI have prompted warnings about use of these drugs during pregnancy (159). Access to clinicians who can provide postexposure care should be available during all working hours, including nights and weekends. Hepatitis B Vaccination Any person who performs tasks involving contact with blood, blood-contaminated body fluids, other body fluids, or sharps should be vaccinated against hepatitis B (2,21). Prevaccination serologic screening for previous infection is not indicated for persons being vaccinated because of occupational risk, unless the hospital or health-care organization considers screening cost-effective. Hepatitis B vaccine can be administered at the same time as other vaccines with no interference with antibody response to the other vaccines (164). If the vaccination series is interrupted after the first dose, the second dose should be administered as soon as possible. The second and third doses should be separated by an interval of at least 2 months. Revaccinated persons should be retested at the completion of the second vaccine series. Persons who do not respond to an initial 3-dose vaccine series have a 30%-50% chance of responding to a second 3-dose series (165). Booster doses of hepatitis B vaccine are not necessary, and periodic serologic testing to monitor antibody concentrations after completion of the vaccine series is not recommended. Any blood or body fluid exposure sustained by an unvaccinated, susceptible person should lead to the initiation of the hepatitis B vaccine series. Treatment of an Exposure Site Wounds and skin sites that have been in contact with blood or body fluids should be washed with soap and water; mucous membranes should be flushed with water. No evidence exists that using antiseptics for wound care or expressing fluid by squeezing the wound further reduces the risk of bloodborne pathogen transmission; however, the use of antiseptics is not contraindicated. Blood, fluid containing visible blood, or other potentially infectious fluid (including semen; vaginal secretions; and cerebrospinal, synovial, pleural, peritoneal, pericardial, and amniotic fluids) or tissue can be infectious for bloodborne viruses. For skin exposure, follow-up is indicated only if it involves exposure to a body fluid previously listed and evidence exists of compromised skin integrity. In the clinical evaluation for human bites, possible exposure of both the person bitten and the person who inflicted the bite must be considered. If a bite results in blood exposure to either person involved, postexposure follow-up should be provided. Procedures should be followed for testing source persons, including obtaining informed consent, in accordance with applicable state and local laws. Confirmation of a reactive result by Western blot or immunofluorescent antibody is not necessary to make initial decisions about postexposure management but should be done to complete the testing process and before informing the source person. For example, an exposure that occurs in a geographic area where injection-drug use is prevalent or involves a needle discarded in a drug-treatment facility would be considered epidemiologically to have a higher risk for transmission than an exposure that occurs in a nursing home for the elderly. Testing of needles or other sharp instruments implicated in an exposure, regardless of whether the source is known or unknown, is not recommended. The reliability and interpretation of findings in such circumstances are unknown, and testing might be hazardous to persons handling the sharp instrument. Such exposures usually involve persons for whom hepatitis B vaccination is recommended. Any blood or body fluid exposure to an unvaccinated person should lead to initiation of the hepatitis B vaccine series. The hepatitis B vaccination status and the vaccine-response status (if known) of the exposed person should be reviewed. The exposed person does not need to modify sexual practices or refrain from becoming pregnant. However, the decision to use any antiretroviral drug during pregnancy should involve discussion between the woman and her health-care provider(s) regarding the potential benefits and risks to her and her fetus. Reports of fatal lactic acidosis in pregnant women treated with a combination of d4T and ddI have prompted warnings about these drugs during pregnancy. The addition of a third drug should be considered for exposures that pose an increased risk for transmission. Reevaluation of the exposed person should be considered within 72 hours postexposure, especially as additional information about the exposure or source person becomes available. The high rate of false positive results of these tests in this setting could lead to unnecessary anxiety and/or treatment (170,171). If toxicity is noted, modification of the regimen should be considered after expert consultation; further diagnostic studies may be indicated. These symptoms often can be managed with antimotility and antiemetic agents or other medications that target the specific symptoms without changing the regimen. Public Health Service statement on management of occupational exposure to human immunodeficiency virus, including considerations regarding zidovudine postexposure use. Public Health Service Task Force on the use of zidovudine to reduce perinatal transmission of human immunodeficiency virus. Update: universal precautions for prevention of transmission of human immunodeficiency virus, hepatitis B virus, and other bloodborne pathogens in health-care settings. The potential for transmission of human immunodeficiency virus through human bites. Accidental hepatitis-B-surface-antigen-positive inoculations: use of e antigen to estimate infectivity. Hemodialysis-associated hepatitis: a report of an epidemic with further evidence on mechanisms of transmission. Hepatitis B infection in physicians: results of a nationwide seroepidemiologic survey. Occupational exposure to hepatitis B virus in hospital personnel: infection or immunization? The risk of hepatitis B infection among health professionals in the United States: a review. Prevention of perinatally transmitted hepatitis B virus infections with hepatitis B immune globulin and hepatitis B vaccine. Perinatal hepatitis B virus transmission in the United States: prevention by passive-active immunization. Efficacy of hepatitis B immune globulin for prevention of perinatal transmission of the hepatitis B virus carrier state: final report of a randomized double-blind, placebo-controlled trial. Hepatitis B immune globulin for accidental exposures among medical personnel: final report of a multicenter controlled trial. A randomized, double blind controlled trial of the efficacy of immune serum globulin for the prevention of post-transfusion hepatitis: a Veterans Administration cooperative study. Hepatitis B "immune" globulin: effectiveness in prevention of dialysis-associated hepatitis. Pediatric experience with recombinant hepatitis B vaccines and relevant safety and immunogenicity studies. Hepatitis B vaccine: demonstration of efficacy in a controlled clinical trial in a high-risk population in the United States. The prevention of hepatitis B with vaccine: report of the Centers for Disease Control multi-center efficacy trial among homosexual men. Hepatitis B vaccine in patients receiving hemodialysis: immunogenicity and efficacy. Postmarketing surveillance for neurologic adverse events reported after hepatitis B vaccination: experience of the first three years. Guillain-Barre syndrome following immunisation with synthetic hepatitis B vaccine [Letter]. Central-nervous-system demyelination after immunisation with recombinant hepatitis B vaccine. The development of rheumatoid arthritis after recombinant hepatitis B vaccination. Confavreux C, Suissa S, Saddier P, Bourdes V, Vukusic S, Vaccines in Multiple Sclerosis Study Group. Hepatitis C virus infection in healthcare workers: risk of exposure and infection. Risk of hepatitis C seroconversion after occupational exposure in health care workers. Risk factors for hepatitis C virus infection among health care personnel in a community hospital. Multicenter study of hepatitis C virus infection in chronic hemodialysis patients and hemodialysis center staff members. Outbreak of hemodialysis-associated non-A, non B hepatitis and correlation with antibody to hepatitis C virus. Efficacy of prophylactic gamma globulin in preventing non-A, non-B post-transfusion hepatitis. Prevention of post-transfusion non-A, non-B hepatitis by non-specific immunoglobulin in heart surgery patients. Effect of immune globulin on the prevention of experimental hepatitis C virus infection. High-dose interferon-a2b treatment prevents chronicity in acute hepatitis C: a pilot study. Interferon therapy for acute hepatitis C viral infection-a review by meta-analysis. Long-term mortality and morbidity of transfusion associated non-A, non-B, and type C hepatitis: a National Heart, Lung, and Blood Institute collaborative study. Occupational risk of human immunodeficiency virus infection in healthcare workers: an overview. Update: human immunodeficiency virus infections in health-care workers exposed to blood of infected patients. Frequency of nonparenteral occupational exposures to blood and body fluids before and after universal precautions training. Efficacy of gloves in reducing blood volumes transferred during simulated needlestick injury. Cytotoxic T lymphocyte responses in the peripheral blood of children born to human immunodeficiency virus-1-infected mothers. Cellular targets of infection and route of viral dissemination after an intravaginal inoculation of simian immunodeficiency virus into rhesus macaques. Efficacy of postexposure prophylaxis after intravaginal exposure of pig-tailed macaques to a human-derived retrovirus (human immunodeficiency virus type 2).

It is preferable to count the undiluted fluid in fewer than 10 squares birth control pills levonorgestrel generic yasmin 3.03 mg on line, if possible birth control for women 40 and over discount yasmin 3.03mg. Calculate the number of cells per liter as follows: Total cells counted X dilution factor X volume factor = cells/?l Example: If 10 squares are counted birth control for women 0ver order 3.03mg yasmin with mastercard, the volume counted is 1?l (10mm2 x 0 birth control facts purchase 3.03 mg yasmin visa. Rinse a disposable Pasteur pipette with glacial acetic acid birth control pills xanax cheap yasmin uk, drain it carefully birth control pills vs depo cheap yasmin, wipe the outside completely dry with gauze, and touch the tip of the pipette to the gauze to remove any excess acid. Mix the spinal fluid with the acid coating the pipette by placing the pipette in a horizontal position and removing your finger from the end of the pipette. With the low-power objective, quickly scan both ruled areas of the hemocytometer to determine whether white cells are present, and to get a rough idea of their concentration. The white cell nuclei will appear as dark, retractile structures surrounded by a halo of cytoplasm. Using the low-power objective, count the white cells in 10mm2, 5mm2 on each side of the hemocytometer using the four corner squares and the center square 7. Do a chamber differential as the white cells are counted by classifying each white cell seen as polynuclear or mononuclear. This chamber differential is inaccurate, and a differential cell counts on a stained cytocentrifuged preparation is preferred. If it appears that the number of white cells is more than 200 cells per ten squares, count fewer squares and adjust your calculations accordingly. These cavities are lined by a contiguous membrane that forms a double layer of mesothelial cells, called the serous membrane. The cavities are the pleural (around the lungs), pericardial (around the heart), and peritoneal (around the abdominal and pelvic organs) cavities. A small about of serous fluid fills the space between the two layers and serves to lubricate the surfaces of these membranes as they move against each other. The fluids are ultrafiltrates of plasma, which are continuously formed and reabsorbed, leaving only a very small volume within the cavities. Since normal serous fluids are formed as an ultrafiltrate of plasma as it filters through the capillary endothelium, they are transudates. In determining the cause of an effusion, it is helpful to 427 Hematology determine whether the effusion is a transudate or an exudate. In general, the effusion is a transudate (which is an ultrafiltrate of plasma) as the result of a systemic disease. An example of a transudate includes ascites, an effusion into the peritoneal cavity, which might be caused by liver cirrhosis or congestive heart failure. Transudates may be thought of as the result of a mechanical disorder affecting movement of fluid across a membrane. Exudates are usually effusions that result from an inflammatory response to conditions that directly affect the serous cavity. At least three anticoagulated tubes of fluids are generally collected and used as follows: 1. A sterile heparinized tube for Gram stain and culture Gross appearance Normal serous fluid is pale and straw colored. An abnormally colored fluid may appear milky (chylous or pseudochylous), cloudy, or bloody on gross 429 Hematology observation. A cloudy serous fluid is often associated with an inflammatory reaction, either bacterial or viral. Blood-tinged fluid can be seen as a result of a traumatic tap, and grossly bloody fluid can be seen when an organ such as the spleen or liver or a blood vessel has rupture. Bloody fluids are also seen in malignant diseases states, after myocardial infarction, in tuberculosis, in rheumatoid arthritis, and in systemic lupus erythematosus. Clotting To observe the ability of the serous fluid to clot, the specimen must be collected in a plain tube with no anticoagulant. Red and white Blood cell count Cell counts are done on well-mixed anticoagulated serous fluid in a hemocytometer. If significant protein is present, acetic acid cannot be used as a diluent for white cell counts, owing to the precipitation of protein. In this case, saline may be used as a diluent and the red and white cell counts are done simultaneously. A predominance of lymphocytes suggests viral infection, tuberculosis, lymphoma, or malignancy. Red cell counts of more than 10000/?l may be seen as effusion with malignancies, infarcts, and trauma. Slides are generally stained with Wright stain, and a differential cell count is done. The white cells generally resemble those seen in peripheral blood, with the addition of mesothelial lining cells. Generally 300 cells are counted and differentiated as to percentage of each cell type see. If any malignant tumor cells are seen or appear to be present, the slide must be referred to a pathologist or 431 Hematology qualified cytotechnologist. Normal synovial fluid is an ultrafiltrate of plasma with the addition of a high molecular-weight mucopolysaccharide called hyaluronate or hyaluronic acid. The presence of hyaluronate differentiates synovial fluid from other serous fluids and spinal fluid. It is responsible for the normal viscosity of synovial fluid, which serves to lubricate the joints so that they move freely. This normal viscosity is responsible for some difficulties in the examination of synovial fluid, especially in performing cell counts. Normal synovial fluid Normal synovial fluid is straw colored and viscous, resembling uncooked egg white. About 1ml of synovial fluid is present in each large joint, such as the knee, ankle, hip, elbow, wrist, and shoulder. In normal synovial fluid the white cell count is low, less than 200/?l, 432 Hematology and the majority of the white cells are mononuclear, with less than 25% neutrophils. Since the fluid is an ultrafiltrate of plasma, normal synovial fluid has essentially the same chemical composition as plasma without the larger protein molecules. Aspiration and analysis the aspiration and analysis of synovial fluid may be done to determine the cause of joint disease, especially when accompanied by an abnormal accumulation of fluid in the joint (effusion). The joint disease (arthritis) might be crystal induced, degenerative, inflammatory, or infectious. Morphologic analysis of cells and crystals, together with Gram stain and culture, will help in the differentiation. Effusion of synovial fluid is usually present clinically before aspiration, and therefore it is often possible to aspirate 10 to 20ml of the fluid for laboratory examination, although the volume (whit is normally about 1ml) may be extremely small, so that the laboratory receives only a drop of fluid contained in the aspiration syringe. The fluid is collected with a disposable needle and plastic syringe, to avoid contamination with confusing birefringent material. A plain tube (without anticoagulant) for clot formation, gross appearance, and chemical and immunologic procedures. This is especially true when only a small volume of fluid is aspirated, giving an excess of anticoagulant, which may crystallize. Normal synovial fluid does not clot, and therefore an 434 Hematology anticoagulant is unnecessary. However, infectious and crystal-induced fluids tend to form fibrin clots, making an anticoagulant necessary for adequate cell counts and an even distribution of cells and crystals for morphologic analysis. Although an anticoagulant will prevent the formation of fibrin clots, it will not affect viscosity. Therefore, if the fluid is highly viscous, it can be incubated for several hours with a 0. Routine examination of synovial fluid the routine examination of synovial fluid should include the following 1. Other tests, as necessary Gross appearance the first step in the analysis of synovial fluids is to 435 Hematology observe the specimen for color and clarity. To test for clarity, read newspaper print through a test tube containing the specimen. As the cell and protein content increases, or crystals precipitate, the turbidity increases, and the print becomes more difficult to read. In a traumatic tap of he joint, blood will be seen in the collection tubes in an uneven distribution with streaks of blood in the aspiration syringe. Xanthochromia in the supernatant fluid indicates bleeding in the joint, but is difficult to evaluate because the fluid is normally yellow. A dark-red or dark-brown supernatant is evidence of joint bleeding rather than a traumatic tap Viscosity Viscosity is most easily evaluated at the time of arthrocentesis by allowing the synovial fluid to drop from the end of the needle. Anything that decreases the hyaluronic acid content of synovial fluid lowers its viscosity. However, this test is of questionable value, as results rarely change the diagnosis and are essentially the same as with the string test for viscosity. Therefore, it is no longer recommended as part of the routine synovial fluid analysis. Red cell and White Blood cell count the appearance of a drop of synovial fluid under an ordinary light microscope can be helpful in estimating the cell counts initially and in demonstrating the presence of crystals. The presence of only a few white cells per high power field suggests a noninflammatory disorder. A large number of white cells would indicate inflammatory or infected synovial fluid. When cells are counted in other fluid, such as blood, the usually diluting fluid is dilute acetic acid. If it is necessary to lyse red blood cells, either hypotonic saline or saponinized saline can be used as a diluent. Since acetic acid cannot be used as a diluent, both red and white cells are enumerated at the same time. This is most easily accomplished by using a phase-contrast rather than a brightfield microscope. Cell counts below 200/?l with less than 25% polymorphonuclear cells and no red cells are normally observed in synovial fluid. A low white cell count (200 to 2000/?l) with predominantly mononuclear cells suggests a noninflammatory joint fluid, while a high white cell count suggests inflammation and a very high white cell count with a high proportion of polymorphonuclear cells strongly suggests infection. Eosinophilia may be seen in metastatic carcinoma to the synovium, acute rheumatic fever, and rheumatoid arthritis. It is also associated with parasitic infections and Lyme disease and has occurred after arthrography and radiation therapy. Each product or fraction varies in its individual composition, each contributing to the whole specimen. During ejaculation, 439 Hematology the products are mixed in order to produce the normal viscous semen specimen or ejaculate. These include assessment of fertility or infertility, forensic purposes, determination of the effectiveness of vasectomy, and determination of the suitability of semen for artificial insemination procedures. Collection of semen specimen Give the person a clean, dry, leak-proof container, and request him to collect a specimen of semen at home following 3-7 days of sexual abstinence. When a condom is sued to collect the fluid, this must be well washed to remove the powder which coats the rubber. Coitus interruptus method of collection should not be used because the first portion of the ejaculate (often containing the highest concentration of spermatozoa) may be lost. Also the acid pH of vaginal fluid can affect sperm motility and the semen may become contaminated with cells and bacteria. During transit to the laboratory, the fluid should be kept as near as possible to body temperature. Laboratory assays the sample should be handled with car because it may contain infectious pathogens. When investigating infertility, the basic analysis of semen (seminal fluid) usually includes: Examination of a wet preparation to estimate the percentage of motile spermatozoa and viable forms and to look for cells and bacteria. Examination of a stained preparation to estimate the percentage of spermatozoa with normal morphology Measurement of volume Normal semen is thick and viscous when ejaculated. It becomes liquefied usually within 60 minutes due to a fibrinolysin in the fluid. When liquefied, measure the volume of fluid in milliliters using a small graduated cylinder. Estimate the percentage of motile and viable spermatozoa Motility: Place 1 drop (one drop falling from a 21g needle is equivalent to a volume of 10-15?l) of well mixed liquefied semen on a slide and cover with a 20x20mm or 22x22mm cover glass. Ensure the spermatozoa are evenly distributed (if not, re-mix the semen and examine a new preparation). Count a total of 100 spermatozoa, and note out of the hundred how many 442 Hematology are motile. Normal motility: Over 50% of spermatozoa are motile within 60 minutes of ejaculation. When more than 60% of spermatozoa are non-motile, examine an eosin preparation to assess whether the spermatozoa are viable or non-viable. Use the low power objective to focus the specimen and the high power objective to count the percentage of viable and non-viable spermatozoa. A large proportion of non-motile but viable spermatozoa may indicate a structural defect in the flagellum. Using a Pasteur pipette, fill an Improved Neubauer ruled chamber with well-mixed diluted semen.

Fall protection on vehicles and loads 155(1) If a worker may have to climb onto a vehicle or its load at any location where it is not reasonably practicable to provide a fall protection system for the worker birth control for women 7 weeks cheap yasmin 3.03mg amex, an employer must (a) take steps to eliminate or reduce the need for the worker to climb onto the vehicle or its load birth control janelle buy genuine yasmin line, and (b) ensure that the requirements of subsection 159(2) are met birth control pills no period discount yasmin generic. Water danger 157 An employer must ensure that a worker uses an appropriate fall protection system in combination with a life jacket or personal flotation device if the worker (a) may fall into water that exposes the worker to the hazard of drowning birth control 9999 effective discount 3.03 mg yasmin free shipping, or (b) could drown from falling into the water birth control pills 4 weeks discount yasmin online mastercard, from other than a boat birth control for 8 days purchase yasmin in india. Occupational Safety and Health Administration, or (ii) certified as safe for use by a professional engineer, and (e) all workers using the system are trained in its use and limitations. Control zones 161(1) If a control zone is used, an employer must ensure that it (a) is only used if a worker can fall from a surface that has a slope of no more than 4 degrees toward an unguarded edge or that slopes inwardly away from an unguarded edge, and (b) is not less than 2 metres wide when measured from the unguarded edge. General Protection and Prevention Prohibitions 162(1) A person must not enter or work at a work area if more than 20 percent of the lower explosive limit of a flammable or explosive substance is present in the atmosphere. Protective procedures and precautions in hazardous locations 165(1) Repealed 165(2) Repealed 165(3) An employer must ensure that in a hazardous location, (a) equipment used will not ignite a flammable substance, and (b) static electricity is controlled, (i) in the case of conductive containers for flammable or combustible liquids while the contents are being transferred, by electrically bonding the containers to one another and electrically grounding them, and (ii) in other cases, by some other effective means. Internal combustion engines 166(1) An employer must ensure that an internal combustion engine in a hazardous location has a combustion air intake and exhaust discharge that are (a) equipped with a flame arresting device, or (b) located outside the hazardous location. Industrial furnaces and fired heaters 168(1) An employer must ensure that (a) a gas or oil fired furnace is designed, operated, monitored, controlled and maintained in a manner that minimizes the possibility of internal explosion of the fire box, and (b) if the furnace is heating flammable substances, there are no connections between the process medium supply system and the fuel supply system or another system connected to the inside of the fire box of the furnace. Hot work 169(1) Despite any other section in this Part, an employer must ensure that hot work is done in accordance with subsections (2) and (3) if (a) the work area is a hazardous location, or (b) the work area is not normally a hazardous location but an explosive atmosphere may exist for a limited time because (i) a flammable substance is or may be in the atmosphere of the work area, (ii) a flammable substance is or may be stored, handled, processed or used in the location, (iii) the hot work is on or in an installation or item of equipment that contains a flammable substance or its residue, or (iv) the hot work is on a vessel that contains residue that may release a flammable gas or vapour when exposed to heat. Hot taps 170(1) An employer must develop procedures in a hot tap plan specific to the type or class of hot tap work being performed before hot tap work begins. Horizontal cylinder storage 173(1) An employer must ensure that a compressed gas cylinder that is horizontal when it is transported or used in a vehicle (a) is in a storage compartment that incorporates a structure of sufficient strength to prevent the cylinder from passing through it should the valve end of the cylinder be damaged and vent its contents in an uncontrolled manner, (b) is in a storage compartment that incorporates a means of securing the cylinder that stops the cylinder from moving within the compartment and that puts the bottom of the cylinder in direct contact with the structure in clause (a), and (c) is protected against scoring during insertion into, and removal from, the storage compartment. Emergency transportation 180(1) Before workers are sent to a work site, the employer must ensure that arrangements are in place to transport injured or ill workers from the work site to the nearest health care facility. First aid providers 181(1) An employer must ensure that the number of first aiders at a work site and their qualifications and training comply with Schedule 2, Tables 5, 6 or 7. Record of injury or illness 183(1) An employer must record every acute illness or injury that occurs at the work site in a record kept for the purpose as soon as is practicable after the illness or injury is reported to the employer. First aid records access 184(1) this section applies to records of first aid given to a worker. Lighting 186(1) An employer must ensure that lighting at a work site is sufficient to enable work to be done safely. Pallets and storage racks 187(1) An employer must ensure that pallets used to transport or store materials or containers are loaded, moved, stacked, arranged and stored in a manner that does not create a danger to workers. Restraining hoses and piping 188(1) An employer must ensure that a hose or piping and its connections operating under pressure are restrained if workers could be injured by its movement if it fails or if it is disconnected. Securing equipment and materials 189 If a worker may be injured if equipment or material is dislodged, moved, spilled or damaged, both the employer and the worker must take all reasonable steps to ensure the equipment or material is contained, restrained or protected to eliminate the potential danger. Skeleton structures 190(1) An employer must ensure that the erection drawings and procedures for a project that includes connecting the structural parts of a skeleton structure are prepared and certified by a professional engineer. Signallers 191(1) If this Code requires signals to be given by a designated signaller, an employer must designate a competent worker to give the signals. Stabilizing masonry walls 192 An employer must ensure that temporary supporting structures (a) are used to stabilize a masonry wall that is more than 2 metres high during its erection, and (b) are not removed until the wall is permanently stabilized. Vehicle traffic control 194(1) If vehicle traffic at a work site is dangerous to workers on foot, in vehicles or on equipment, an employer must ensure that the traffic is controlled to protect the workers. Working on ice 195(1) If a worker is to work on ice and the water beneath the ice is more than 1 metre deep at any point, an employer must ensure the ice will support the load to be placed on it. Adapting heavy or awkward loads 209 If the equipment provided under section 208 is not reasonably practicable in a particular circumstance or for a particular heavy or awkward load, the employer must take all practicable means to (a) adapt the load to facilitate lifting, lowering, pushing, pulling, carrying, handling or transporting the load without injuring workers, or (b) otherwise minimize the manual handling required to move the load. Assessing manual handling hazards 210(1) Before a worker manually lifts, lowers, pushes, pulls, carries, handles or transports a load that could injure the worker, an employer must perform a hazard assessment that considers (a) the weight of the load, (b) the size of the load, (c) the shape of the load, (d) the number of times the load will be moved, and (e) the manner in which the load will be moved. Musculoskeletal injuries 211 If a worker reports to the employer what the worker believes to be work related symptoms of a musculoskeletal injury, the employer must promptly (a) review the activities of that worker, and of other workers doing similar tasks, to identify work-related causes of the symptoms, if any, and (b) take corrective measures to avoid further injuries if the causes of the symptoms are work related. Verifying isolation 213 A worker must not perform work on machinery, equipment or powered mobile equipment to be serviced, repaired, tested, adjusted or inspected until (a) the actions required by subsection 212(1) are completed, (b) the machinery, equipment, or powered mobile equipment is tested to verify that it is inoperative, and (c) the worker is satisfied that it is inoperative. Securing by a group 215(1) If a large number of workers is working on machinery, equipment or powered mobile equipment, or a number of energy-isolating devices must be secured, an employer may use a group procedure in accordance with subsections (2) through (6). Noise management program 221(1) If a noise exposure assessment confirms that workers are exposed to excess noise at a work site, the employer must develop and implement a noise management program that includes policies and procedures. Transported loads, equipment and buildings 226 the safe limit of approach distances listed in Schedule 4 do not apply to a load, equipment or building that is transported under energized overhead power lines if the total height, including equipment transporting it, is less than 4. Utility worker and tree trimmer exemption 227 Section 225 does not apply to utility workers, qualified utility workers or utility tree trimmers working in accordance with the requirements of the Alberta Electrical and Communication Utility Code (2002). Flame Resistant Clothing Use of flame resistant clothing 232(1) If a worker may be exposed to a flash fire or electrical equipment flashover, an employer must ensure that the worker wears flame resistant outerwear and uses other protective equipment appropriate to the hazard. Foot Protection Footwear 233(1) An employer must ensure that a worker uses footwear that is appropriate to the hazards associated with the work being performed and the work site. All-terrain vehicles, snow vehicles, motorcycles 236(1) An employer must ensure that a worker riding an all-terrain vehicle, snow vehicle, motorized trail bike or motorcycle or, subject to subsection (2), a small utility vehicle at a work site wears a safety helmet approved to one of the following standards: (a) U. Use of jackets and flotation devices 241(1) If there is a foreseeable danger that a worker could be exposed to the hazard of drowning, an employer must ensure that the worker wears a life jacket. Code of practice 245(1) If respiratory protective equipment is used at a work site, an employer must prepare a code of practice governing the selection, maintenance and use of respiratory protective equipment. Equipment no immediate danger 252 An employer must ensure that a worker wears self-contained breathing apparatus or an air line respirator having a capacity of at least 30 minutes if (a) the employer determines under section 244 that conditions at the work site are not or cannot become immediately dangerous to life or health but (i) the oxygen content of the atmosphere is or may be less than 19. Air purifying equipment 253 An employer may permit workers to wear air purifying respiratory protective equipment if (a) the oxygen content of the air is, and will continue to be, 19. Emergency escape equipment 254(1) Despite sections 251 and 252, if normal operating conditions do not require the wearing of respiratory protective equipment but emergency conditions may occur requiring a worker to escape from the work area, the employer may permit the escaping worker to wear (a) a mouth bit and nose-clamp respirator if (i) the respirator is designed to protect the worker from the specific airborne contaminants present, and (ii) the oxygen content of the atmosphere during the escape is 19. Abrasive blasting operations 255 If a worker is performing abrasive blasting, the employer must ensure that the worker wears a hood specifically designed for abrasive blasting, supplied with air that is at a positive pressure of not more than 140 kilopascals. Dangerous movement 258(1) If the movement of a load or the cab, counterweight or any other part of powered mobile equipment creates a danger to workers, (a) an employer must not permit a worker to remain within range of the moving load or part, and (b) the operator must not move the load or the equipment if a worker is exposed to the danger. Pedestrian traffic 259(1) An employer must ensure that, if reasonably practicable, (a) walkways are designated that separate pedestrian traffic from areas where powered mobile equipment is operating, (b) workers use the designated walkways. Starting engines 262(1) Subject to subsection (3), an employer must ensure that a worker does not start the power unit of powered mobile equipment if the drive mechanisms and clutches of the equipment are engaged. Unattended equipment 263(1) A person must not leave the controls of powered mobile equipment unattended unless the equipment is secured against unintentional movement by an effective method of immobilizing the equipment. Lights 264(1) An employer must ensure that powered mobile equipment operated during hours of darkness or when, due to insufficient light or unfavourable atmospheric conditions, workers and vehicles are not clearly discernible at a distance of at least 150 metres, is equipped with lights that illuminate (a) a direction in which the equipment travels, (b) the working area around the equipment, and (c) the control panel of the equipment. Windows and windshields 265(1) An employer must ensure that glazing used as part of the enclosure for a cab, canopy or rollover protective structure on powered mobile equipment is safety glass or another non-shattering material providing at least equivalent protection. Other safety equipment 266 An employer must ensure that powered mobile equipment has (a) a device within easy reach of the operator that permits the operator to stop, as quickly as possible, the power unit, drawworks, transmission or any ancillary equipment driven from the powered mobile equipment, including a power take-off auger or digging, lifting, or cutting equipment, (b) an effective means of warning workers of the presence, general dimensions and movement of the equipment if the presence, dimensions or movement may be a danger to a worker, (c) seats or other installations sufficient to ensure the safety of the operator and other workers who may be in or on the equipment while it is in motion, and (d) safety clips on the connecting pins if the powered mobile equipment is equipped with a trailer hitch. Bulkheads 268 An employer must install a bulkhead or provide other effective means to protect the operator of a vehicle transporting equipment or materials that may shift during an emergency stop. Guards and screens 269 An employer must ensure that powered mobile equipment has a cab, screen, shield, grill, deflector, guard or other adequate protection for the operator if the hazard assessment indicates there is a significant possibility that the operator may be injured by flying or projecting objects. Rollover protective structures 270(1) An employer must ensure that the following types of powered mobile equipment weighing 700 kilograms or more have rollover protective structures: (a) tracked (crawler) or wheeled bulldozers, loaders, tractors or skidders, other than those operating with side booms; (b) back hoes with a limited horizontal swing of 180 degrees; (c) motor graders; (d) self-propelled wheeled scrapers; (e) industrial, agricultural and horticultural tractors, including ride-on lawnmowers; (f) wheeled trenchers. Recertification after modification 273 An employer must ensure that any addition, modification, welding or cutting of a rollover protective structure or a falling objects protective structure is done in accordance with the instructions of, and is re-certified as restored to its original performance requirements by, the equipment manufacturer or a professional engineer. Fuel tank in cab 274 An employer must ensure that a fuel tank located in the enclosed cab of a unit of powered mobile equipment has a filler spout and vents (a) extending outside the cab, and (b) that are sealed to prevent vapours from entering the enclosed cab. Tank trucks 278(1) the operator must ensure that a tank truck containing flammable, combustible or explosive materials is bonded and grounded while (a) its loading lines are connected or disconnected, and (b) the contents of the tank truck are being transferred. All-Terrain Vehicles and Snow Vehicles Three-wheeled all-terrain cycles 280 A person must not use a three-wheeled all-terrain vehicle at a work site. Load and slope limitations 282(1) the operator of an all-terrain vehicle or snow vehicle must ensure that, if it is used to move a load, the load conforms to the weight, height and other limits specified by the manufacturer of the all-terrain vehicle or snow vehicle. Seat belt 284 If a forklift truck is equipped with a seat belt by the original equipment manufacturer or a seat belt is added to the equipment at some later date, an employer must ensure that the seat belt is present and in useable condition. Pile Driving Equipment and Practices Chocking 285 the operator of pile driving equipment must ensure that a pile hammer is securely chocked while suspended by the hammer line if the equipment is not operating. Pile hoisting 286(1) the operator of pile driving equipment must ensure that pilings are not hoisted in the leads if workers who are not directly involved in the pile hoisting are on the superstructure or within range of a falling pile. Restraining hoses and connections 287 An employer must ensure that the pressure hoses of pile driving equipment with pressure hammers have, on the pressure side of all hose connections, safety chains or ropes designed to protect workers should the hoses or connections fail. Timber piles 289 the employer must ensure that (a) workers in the area of a timber pile being struck by a pile driver are protected from any danger that may result from the pile shattering, and (b) before piles are placed in position for driving, pile heads are cut square and timber piles are free of debris, bark and splintered wood. Load ratings 293(1) An employer must ensure that the maximum load rating of the rigging, as determined by the rigging manufacturer or a professional engineer, is legibly and conspicuously marked on the rigging. Prohibition 295 A worker must not use rigging that does not comply with this Part. Rigging protection 296 An employer must ensure that sharp edges on loads to be hoisted are guarded to prevent damage to the slings or straps of the rigging. Cable clips 300(1) An employer must ensure that U-bolt type clips used for fastening wire rope are installed (a) so that the U-bolt section of the clip bears on the short or ?dead? side of the rope, (b) so that the saddle of a clip bears on the long or ?live? side of the rope, and (c) using the number and with the spacing that complies with the specifications in Schedule 5. Ferrules 301(1) If a ferrule is used to form an eye loop in a wire rope and (a) the ends of the splice are visible beneath the ferrule, or (b) the ferrule is identified as covering a ?Flemish eye? splice, the employer must ensure that the ferrule is commercially manufactured of steel and properly swaged onto the splice. Matching components 302(1) An employer must ensure that the wire ropes, sheaves, spools and drums used in rigging have a diameter of not less than the diameter specified by the manufacturer for use in that circumstance. Safety latches 303(1) An employer must ensure that a hook has a safety latch, mousing or shackle if the hook could cause injury if it is dislodged while in use. Rejection Criteria Synthetic fibre slings 305(1) An employer must ensure that a synthetic fibre web sling is permanently removed from service if it is damaged or worn as follows: (a) the length of the edge cut exceeds the web thickness; (b) the depth of an abrasion is more than 15 percent of the webbing thickness, taken as a proportion of all plies; (c) the total depth of the abrasion on both sides of the webbing is more than 15 percent of the webbing thickness, taken as a proportion of all plies; (d) the depth of the warp thread damage is up to 50 percent of the webbing thickness and the damage (i) is within 25 percent of the sling width of the edge, or (ii) covers 25 percent of the sling width, (e) the warp thread damage is as deep as the sling is thick (i) in an area that is within 25 percent of the sling width of the edge, or (ii) over an area that is more than 12. Electric arc damage 308 An employer must ensure that a component of rigging that has been contacted by an electric arc is removed from service unless a professional engineer certifies that it is safe to use. Damaged hooks 309 An employer must ensure that a worn, damaged or deformed hook is permanently removed from service if the wear or damage exceeds the specifications allowed by the manufacturer. No safeguards 312(1) Despite other sections in this Part, an employer may allow the machinery to be operated without the safeguards if (a) safeguards are normally required by this Code for machinery, and (b) the machinery cannot accommodate or operate with these safeguards. Building shafts 313(1) An employer must ensure that if a work platform is necessary to ensure the safety of workers in a building shaft, there is (a) a main work platform that is completely decked and designed to support any anticipated load, and (b) a second platform not more than 4 metres below the main work platform. Covering openings 314(1) An employer must ensure that an opening or hole through which a worker can fall is protected by (a) a securely attached cover designed to support an anticipated load, or (b) guardrails and toe boards. Guardrails 315(1) An employer must ensure that a guardrail required by this Code (a) has a horizontal top member installed between 920 millimetres and 1070 millimetres above the base of the guardrail, (b) has a horizontal, intermediate member spaced mid-way between the top member and the base, (c) has vertical members at both ends of the horizontal members with intermediate vertical supports that are not more than 3 metres apart at their centres, and (d) is constructed of lumber that is 38 millimetres by 89 millimetres or of material with properties the same as or better than those of lumber. Hoppers, bins and chutes 316 If a worker can access materials in hoppers, bins or chutes, an employer must ensure the hoppers, bins or chutes have horizontal bars, screens or equally effective safeguards that prevent a worker from falling into the hoppers, bins or chutes. Machine failure 317 If a worker may be injured if a machine fails, an employer must install safeguards on the machine strong enough to contain or deflect flying particles of material, broken parts of machinery and a shock wave. Protection from falling objects 318(1) An employer must ensure that workers in a work area where there may be falling objects are protected from the falling objects by an overhead safeguard. Push stick or block 319 If a worker may be injured while feeding materials into cutting or shaping machinery, an employer must ensure the machine worker uses a push stick, push block or other similar means of feeding the material. Toe boards 321(1) An employer must ensure that (a) a toe board required by this Code is not less than 140 millimetres in height above the surface of the work area, and (b) the space between the bottom of the toe board and the surface of the work area is not more than 6 millimetres high. Wire mesh 322 An employer must ensure that wire mesh used in a safeguard required by this Code is (a) fabricated of wire at least 1. Design 324(1) An employer must ensure that a single pole or double pole scaffold is (a) supported against lateral movement by adequate bracing, (b) anchored by one tie-in for each 4. Tagging requirements 326(1) An employer must ensure that a scaffold is colour coded using tags at each point of entry indicating its status and condition as follows: (a) a green tag with ?Safe for Use?, or similar wording, to indicate it is safe for use; (b) a yellow tag with ?Caution: Potential or Unusual Hazard?, or similar wording, to indicate the presence of a potential or unusual hazard; (c) a red tag with ?Unsafe for Use?, or similar wording, to indicate it is not safe to use. Working from a ladder 328(1) An employer must ensure that no worker performs work from a ladder that is used to give access to the working levels of a scaffold. Scaffold platform 330(1) An employer must ensure that the platform of a scaffold (a) is a minimum width of 500 millimetres, except that a nominal 300 millimetre wide platform may be used with ladderjacks, pump jacks or similar systems, (b) does not have an open space between the platform and a structure that is greater than 250 millimetres in width, (c) if not level, is designed to ensure adequate footing for workers using the platform, and (d) is continuous around obstructions that would create openings into or through which a worker might step or fall through. Free-standing or rolling scaffolds 334(1) An employer must ensure that (a) the height of a free-standing or rolling scaffold is not more than 3 times its smallest base dimension, (b) if outriggers are used to attain the 3 to 1 ratio, the outriggers are firmly attached and ensure the stability of the scaffold, (c) if a vehicle is used instead of scaffold wheels to form a rolling scaffold, all parts of the scaffold are securely fastened together and the scaffold is securely attached to the vehicle, (d) if outriggers are required to maintain the stability of a vehicle-mounted scaffold, the outriggers are securely attached to the frame of the vehicle, and (e) a rolling scaffold is equipped with locking wheels or there are blocks for the wheels. Half-horse scaffolds 335(1) An employer must ensure that (a) a half-horse scaffold is used only as a light duty scaffold, (b) half-horse scaffold ledgers are not more than 3 metres apart, and (c) half-horse scaffold legs are not spliced or more than 5 metres high. Needle-beam scaffolds 337(1) An employer must ensure that beams supporting a needle-beam scaffold (a) are constructed of lumber, or a material that has properties equal to or greater than those of lumber, (b) are not less than 89 millimetres by 140 millimetres, and (c) are placed on their edge. Roofing brackets 339 An employer must ensure that a roofing bracket is (a) constructed to support the loads that may be put on it, (b) provided with effective non-slip devices, and (c) secured to the roof with nails. Single-pole scaffolds 340 An employer must ensure that (a) a wooden single-pole scaffold is used only as a light duty scaffold and is not more than 9 metres in height, (b) the uprights on a wooden single-pole scaffold are spaced not more than 3 metres apart, and (c) the dimensions and/or strength of members of single-pole scaffolds are not less than those specified in Schedule 6, Tables 7 and 8. Suspended scaffolds 341(1) this section applies to suspended scaffolds other than suspended outrigger scaffolds or suspended swingstage scaffolds. Safety on swingstage scaffolds 344(1) An employer must ensure that if workers are required to be on a swingstage scaffold, the hoisting equipment is equipped with automatically operating locking mechanisms so that the suspension ropes cannot slip or run free. Workers on swingstage scaffolds 345(1) Before starting to work on a swingstage scaffold, a worker must inspect the scaffold to ensure that (a) the thrustouts or parapet hooks are secured in accordance with section 343, and (b) counterweights meet the requirements of section 343. Elevating Platforms and Aerial Devices Worker safety 346(1) An employer must ensure that a worker is not travelling in a basket, bucket, platform or other elevated or aerial device that is moving on a road or work site if road conditions, traffic, overhead wires, cables or other obstructions create a danger to the worker. Fly form deck panels 353(1) An employer must ensure that a fly form deck panel (a) is capable of resisting a minimum horizontal load of 3. Drinking fluids 355(1) An employer must ensure that an adequate supply of drinking fluids is available to workers at a work site. Exception 356 Sections 357 to 361 do not apply to (a) a food establishment or other work site for which there are specific regulations under the Public Health Act, or (b) a mobile or temporary work site at which work is being performed for a period of not more than five working days if the employer has arranged for workers to use local toilet facilities during that period. Toilet facilities 357(1) Subject to subsection (2), an employer must ensure that a work site has the number of toilets for each sex that are required by Schedule 7, in separate toilet facilities.

There is no evidence that problems caused by shortcuts and biases are overcome just by a greater understanding that such shortcuts occur birth control pills yellow pacha buy discount yasmin online. More recent and available information will feel more important even if a person knows why birth control mini pill buy yasmin american express. Biases and heuristics such as recency and availability can lead to an incorrect diagnosis of a situation and confirmation biases can work against the trapping of the problem birth control 6 hours late buy yasmin online now. On the downwind leg in visual conditions birth control 3 month pack discount 3.03 mg yasmin with mastercard, the flight crew was visually searching for a Cessna 172 that they had previously had visual contact with birth control depression purchase yasmin 3.03 mg free shipping. The captain then said the following: I guess? Yeah; before we turned downwind birth control pills and antibiotics discount generic yasmin canada, I saw him about one o? clock?probably behind us now the first part of the communication indicates that the captain was unsure but then found a small piece of evidence to provide some confirmatory support for this preferred consensus, as opposed to challenging it. One might expect (particularly in hindsight) that the non sighting of the Cessna 172 at this point would cause the crew concern and lead to seeking evidence of its whereabouts. But the very fact that they cannot see it becomes evidence supporting the idea that it is behind them. This is entirely normal and natural, even though in hindsight it might appear to some to be reckless. The trainer should quickly move to putting these into reasonable context, rather than producing slides and narrative based on textbooks. If the trainer is confident, knowledgeable and able to apply theory quickly to examples, then extracting examples from delegates can be more fruitful than spending time on case studies. If the trainer is less confident than preparing some small examples from accident reports will prove useful. Despite this the trainer must not give the impression that the various mechanisms that have been developed by evolution can be easily optimised by education or training. It is also important to avoid giving the impression that decision shortcuts are always problematic. There is very little valid evidence that teaching decision-making in general improves decision-making in real world environments. Assessing and observing decisions in the simulator or on line There is always a reason behind the process of shortening a decision, and where the mechanism seems inappropriate the trainer must explore why it was used. If a trainer identifies a shortcut as part of problem, then they must first establish whether that shortcut is routinely used in similar situations. The shortcut may be generally inappropriate, and the training scenario may expose the reason to the crew. However it is likely that the situation was not exactly as perceived by the crew, and the trainer can facilitate some learning about why that shortcut did not work in that situation. The trainer may also discuss ways to add resilience to an inevitable shortcut situation. For example if a crew make a shortcut to allow time to prioritise something else, then putting in place a review or a barrier to error may be appropriate. One can see that a trainer who simply states that using the shortcut was inappropriate is at best missing a good learning opportunity, and at worst re-directing crew resources artificially without considering the unintended consequences. The trainer must find out why that option had higher perceived utility for the crew, not why the crew made the wrong choice. When debriefing such an event it is worth recalling that the utility of a choice is formed of both probability of success and the worth of the choice. The crew may have assessed an option as being likely to work, but it did not work. A common underlying assumption is that because a chosen option did not work, the crew could have known that at the time, or have been able to work it out. Once a scenario has played out, and the consequences of taking a particular option become apparent, the perception of utility will unconsciously change due to hindsight bias (in both the trainer and the crew). If the option worked, the utility will be perceived as higher than it was at the time, whereas if it fails the utility will be viewed as lower than it really was. The trainer must recognise this rather than assuming that if something failed then it had been unlikely to work to begin with. The trainer should avoid the temptation of assessing the decision purely on its consequences later on. Many risk-based decisions taken in flight have an unfortunate characteristic when looked at from the perspective of someone outside the process, or in hindsight. Sometime the chosen option appeared to the crew to represent the least risky choice at the time, but appears to the observer to have been a risky choice in hindsight. The trainer or observer can overcome this natural hindsight bias to try to establish whether the crew felt the decision to be a relatively low risk choice at the time, and why. The level of risk accepted by a crew is not necessarily correlated with the level of risk as seen from outside the decision. Asking what made an option appear less risky than others is usually a more fruitful approach than asking the crew why they took a risk. As a bonus, this approach shows the crew that the trainer is trying to understand the process. The session debrief is usually the best time to dig into a decision, with the obvious disadvantage of memory limitations, given everything else that may have happened in the meantime. Scientists use various techniques to attempt to illicit information about decisions, and the trainer can learn from these. Some effective questions to try to break into a decision process after the event are:? It shows the crew that the trainer understands implicitly that the decision was made for a good reason in terms of informational assessment. The decision may look risky to the trainer, but may have appeared to the crew to be low risk at the time. The trainer can then decide to what extent those factors were reasonably predictable, or linked to the decision process. It is too easy to make the assumption that alternatives would have worked better, without testing them or considering them fully. Having discovered why the crew assessed the situation in the way they did, chose the action they chose, and rejected the alternatives that they rejected, the trainer will be in a strong position to give realistic feedback and assessment of what occurred. It seems that there are times when despite a situation being seemingly ambiguous or complicated an answer ?comes to the mind. There are a number of scientific schools of thought around such decisions, such as the process being emotionally driven, being driven by common unconscious decision biases or the process being primed by deeply learned but ?non-declarable? expertise. The scientist best known for his extensive work on this area in the last few decades is Gary Klein. This means that it is not concerned with clinical laboratory tasks, but with understanding how real people (particularly experts) make critical choices in their real environments (i. Klein spent many years studying and observing various experts in order to describe the process. The decision maker then quickly simulates the first option that comes to their mind and as long as it seems like a satisfactory response, they carry it out. Hence, one fundamental part of recognition-primed decisions is the serial processing of options. This means that a single option is generated and then tested (mentally simulated) before any other options are generated. If the option is satisfactory (if it seems likely to fulfil the objective) then it is acted upon, but this means that there may have been better options that were never considered. This therefore has a strong theoretical similarity to the theory of satisfycing (Simon 1950) that was discussed earlier. Application of Knowledge Very fast decision-making It is arguable that most decisions made on the flight deck could fall into the category of recognition-primed decisions. This is because both crew-members are experienced enough to base choices on past experience. But there are many reasons why the captain would have felt that the situation was typical of one where the decision to take off was appropriate. Indeed the communication using the term ?clearance? was probably enough to cue the captain to take off given his recent simulator experience. He could not see the other aircraft and probably felt that it had cleared the runway, perhaps because he heard the previous conversation that he perceived as indicating that the American ?clipper? would leave the runway. With the perception of a clear runway and the perception that clearance had been given, he made a decision that he had made thousands of times before: to take off. A real world situation can often generate a feeling (in the moment) that it should be safe enough to ?bend the rules? in this case. This happens when a situation has many typical features and the expert does not have the time or capacity to consider everything at that moment. If there is motive or pressure then a decision to go further than agreed becomes more likely and will appear reckless in hindsight but feel acceptable at the time. Specifically the busting of minima or agreed bottom lines can feel acceptable at the time but may be based on partial information. For this reason it is important that pilots are very cautious about allowing themselves to break planned safety limits when under pressure, or even when in seemingly normal circumstances. As a very new commander, I taxied out at Rome with a large thunderstorm cell approaching the airfield on an otherwise clear evening. The traffic behind was offered take off which they accepted and taxied past, along with another aircraft. A very shaken crew reported severe wind shear at lift off and the tower commented that wind was now 50kts across the runway! The process is deeply rooted and cannot simply be improved or made error-free by putting in more effort or employing various techniques or decision aids at the time. It is accepted that recognition primed decision making theory (along with all such intuitive decision theory) is largely descriptive, but not prescriptive. However, this does not mean that knowledge of intuitive decision-making is of no use. Most people are familiar with a feeling about a certain option, or confidence in a choice that they are making, without knowing why (without being able to ?put their finger on it?). It is worth knowing that in many cases such feelings have grounding, even if consciously the reasons cannot be unpacked. This does not mean pilots should always opt for the option that ?feels? better, but that if they feel that one option is better than another, it is worth at least scrutinising why that is the case. Another learning point is that when there is a strong feeling towards a certain option, a pilot should consider whether there are any particularly untypical circumstances. Intuitive decisions are based on typical situations, and so will be less reliable when the situation has certain atypical features (such as in the Tenerife Airport accident example). These atypical features may require more scrutiny because they can easily cause error in intuitive decisions. Intuitive forms of decision-making can easily be examined in the classroom, and case studies can be used to show them. As with other decision making instruction, generating examples from the audience is an effective way to get the point across, as long as the audience participate and the trainer is able to facilitate. However the trainer must also realise the limitations of teaching about intuitive decision making in the classroom, and that just teaching people about the topic will not necessarily be of any use to them in real world situations. In terms of instructors / examiners, knowledge of intuitive processes as one part of overall decision-making area is very useful. It can help the instructor to understand why a crew did what they did, especially when there was little communication around a decision they made. Without overt communication or discussion, a decision can sometimes appear to be unfounded or rushed, when in fact it was soundly based. If the decision leads to an undesirable consequence, then the trainer should not simply state that the crew ought to have spent more time on the decision, without considering whether extra time would have helped (or even been possible), and should try to resolve whether the decision was in fact better than the subsequent situation made it look in hindsight. In general It is useful for trainers to learn about different types and mechanisms of decision-making. A common flaw in the assessing of decision-making is to conclude that any undesirable outcome following a decision could have been prevented by spending more time and effort on the decision. Because of the use of decision aids, good decision-making is often thought to be that which appears to be performed in the manner of a decision acronym, regardless of the circumstances. A poor choice is then said to stem from a decision process (of ?rational decision making?) that was not carried out properly. Decision aids force rational decisions, and so if a rational decision is inappropriate in such circumstances, so is a decision aid. It is important to note that pilots rarely use rational decision making approaches in the manner that trainers might deem appropriate and in most situations it would not be a good idea to make decisions in that way. A further cautionary note is that behavioural marker systems tend to assume rational/classical modes of decision-making. Hence there is a danger that where decisions were not made in classic/rational ways, trainers will deem them to have been poor whenever the situation subsequently deteriorates, regardless of circumstance, or whether it was realistic to expect the crew to implement a rational, acronym-aided, decision process at the time. Stress applied to an airframe or power plant that exceeds the designed load factor leads to weakening or failure of the component affected. Physical stress occurs when external conditions either put a strain on the homeostatic mechanisms of the body or are so extreme as to nullify them. An individual can be likened in some ways to a bucket in that he or she has only a certain capacity. Just as buckets come in different shapes and sizes, so different individuals have different capacities and abilities to cope. Thus continued stress can create physical symptoms such as insomnia, loss of appetite, headache, irritability etc. This stimulus will demand a response, which may be psychological or physiological. It is impossible to live without experiencing some degree of stress, whether at home, during a work role or at leisure. Further, an optimum amount of stress is necessary for an individual to function efficiently and perform a given task such as flying an aeroplane. The first is ?eustress?, which is associated with a feeling of increased energy and ability to deal with the stressor. The second is ?distress?, when the individual feels that events are out of control and there is an inability to cope. Chronic stress is something that continues for a long period of time such as financial difficulties or inter-personal relationship problems.

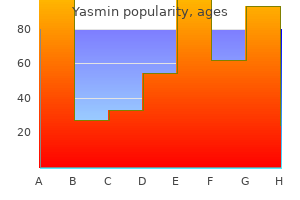

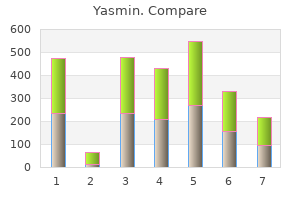

Buy yasmin 3.03mg lowest price. THE WHOLE TRUTH: Male Birth Control.